After finalizing my P-I-P hinge program in Grasshopper 3D, I had been looking for good projects to use it on. There never seem to be enough good barbell collars in the gym so I began wondering if I were able to prototype one.

The design for my 3D printed barbell collar is nothing revolutionary. It is essentially the same as other cheap collars.

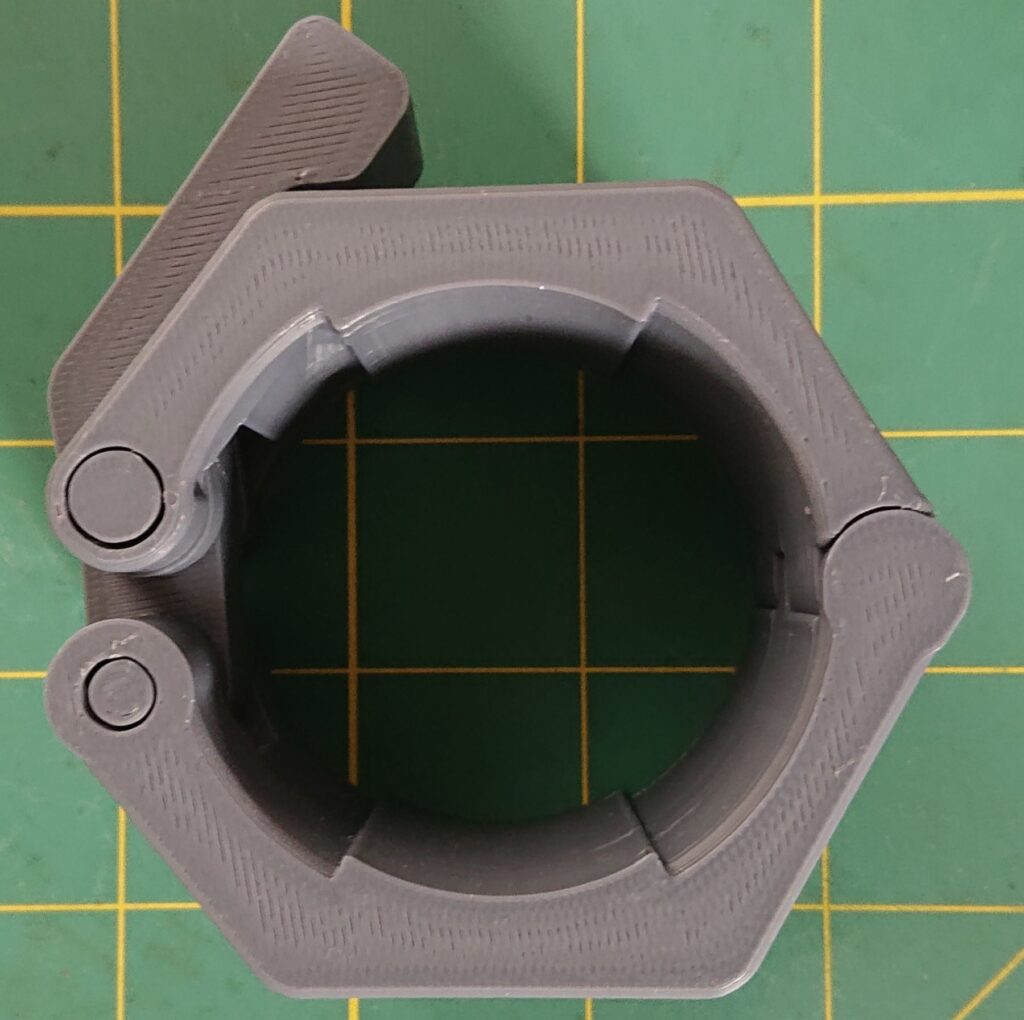

Similar to other projects of mine, I aim to capitalize on the advantages of additive manufacturing. Using the same principles as my PIP hinge design, I am able to make the whole assembly from one print; a part count of one. From a manufacturing perspective, minimizing part count is a great way to cut costs of finished goods. My design requires no assembly, just a bit of support removal.

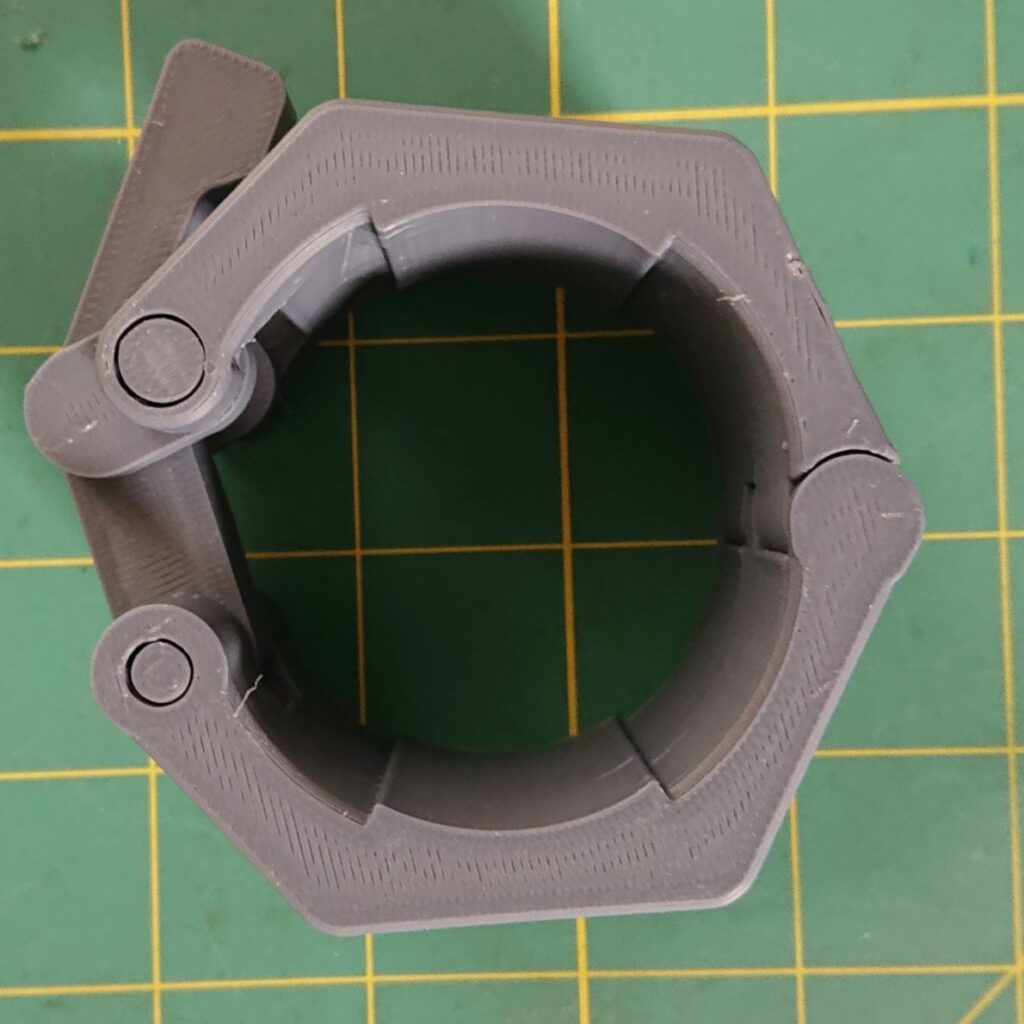

Getting to this first working prototype wasn’t as simple as it should have been. To start, I wanted to be sure my hinge design on the back of the collar would work. My PIP hinge generator worked very well first try.

From there I had to design the latching mechanism. I using the same tolerances as the hinge for my first print. I ended up with a single complex piece, an offset shaft that kind of reminds me of a crankshaft. The tolerances worked well, but I did the latch incorrectly. It didn’t open fully or easily.

I put the latch clip on the short piece of the mechanism. I should have put it on the large piece for better mechanical advantage. The latch action is incorrect and will not work.

After fixing I had a working prototype:

Leave a Reply